Specialist Polyurea Coating, Liquid Waterproofing,

Resimac Tank, Bund & Sump lining

High Wear, Corrosion, Erosion, Temperature, Chemical Attack

Resimac Tank, Bund & Sump lining

High Wear, Corrosion, Erosion, Temperature, Chemical Attack

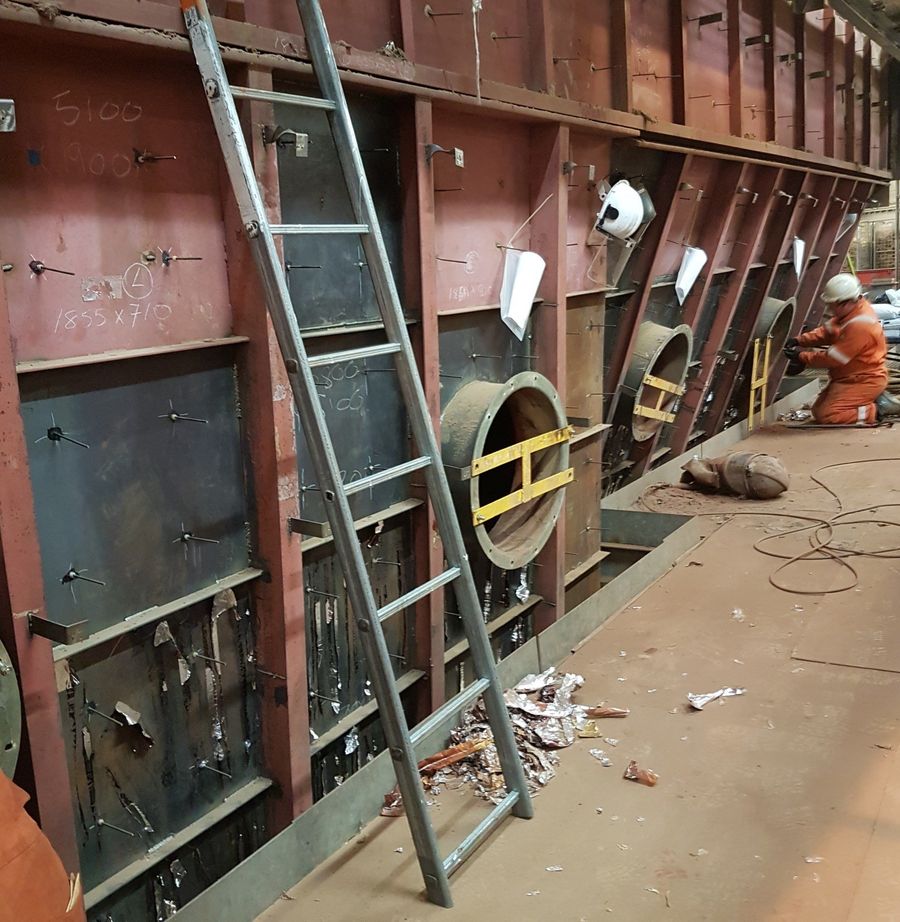

Trident Coatings Industrial Coating & Lining Systems

With over 25 year's experience delivering quality Polyurea, waterproofing, protective coating, blasting & surface preparation services to a wide range of industrial, commercial and domestic projects. From the largest of construction companies to the one off private customer, from petrol chemical plants to water authorities.

Delivering the best for the industry, whatever your looking for from :

Chemical containment

- Tank, Bund and Sump linings

Surface Preparation

- Wet and Dry blasting

- Track blasting

Waterproofing

- Roofing

- Balconies and walkways

- Podium Decks

High Wear, Corrosion, Erosion, Temperature, Chemical Attack

- Pump Housings

- Flanges

- Impellers

- Rudders

- Bow thrusters

- Heat exchangers

- Scrubbers

- Sewers

Industrial Painting

Spray foam insulation Econ Foam Insulation

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Providing the ultimate in protection solutions from water to chemical attack, abrasion to corrosion resistance.

- Polyurea

- Ceramic Coatings

- Solvent free epoxy novolac coating

- Solvent free epoxy with metallic fillers

- Vinylester

- Rubber

- Cementitious Coatings

- Silicone

- Spray foam Insulation

With our own certified CIP coating inspectors that have the capabilities to carry out a full specification review, fault diagnosis and third party inspections. Our consistent focus is on the application of protective coating systems that provide excellent Chemical, corrosion and abrasion control at the best value whilst minimising risk to workers and the environment.

With high performance materials. Many of the products used in our process have been independently tested and their performance verified. In the United Kingdom, the leading testing and approvals house the British Board of Agrément (BBA) has been issuing approvals for some of our systems since 1975.

providing fast and effective solutions for a wide range of industrial applications Call 07930 335 243

Subscribe

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later